Blog test

How to Cut Ceramic Tile Straight: Essential Tile Cutting Techniques

Cutting ceramic tile straight requires careful tool selection and precise techniques. A manual tile cutter with a robust rail system guarantees clean, straight cuts. For intricate tasks, a wet saw equipped with a diamond blade offers superior accuracy. Consistent pressure and alignment during cutting are vital to avoid chipping. Precision and careful handling are important due to the tile’s fragility. Different tools and methods may be needed for more complex tasks. More insights await exploration.

Key Takeaways

- Use a manual tile cutter with a robust rail system for straight, precise cuts.

- Align the tile with a marked line and apply even pressure during cutting.

- Opt for a wet saw with a diamond blade for accurate and clean straight cuts.

- Secure the tile firmly on the cutter’s base to prevent slippage.

- Maintain consistent speed and steady hand movement to avoid chipping.

Best Tile Cutting Tools and Techniques for Ceramics?

Selecting the appropriate tile cutting tool for ceramic tiles involves understanding the specific capabilities of each option.

A manual tile cutter is suitable for straight cuts, offering precision and ease for smaller projects.

For more intricate or larger-scale tasks, a wet saw provides superior accuracy and control, while an angle grinder can be employed for unique cuts. However, careful handling is required to guarantee clean edges.

Choosing the Right Manual Tile Cutter

When starting on a ceramic tile project, understanding which manual tile cutter best fits your needs can make all the difference in achieving clean, precise cuts. A manual tile cutter is an essential cutting tool designed to cut ceramic tile efficiently.

To guarantee a straight cut, select a model with a robust rail system and smooth scoring mechanism. When using this tile cutting tool, place the tile securely onto the tile cutter’s base. By scoring the tile with a titanium-coated wheel, you can achieve the cleanest cut before you snap the tile along the scored line.

High-quality tile cutters offer adjustable guides to maintain precision, making them invaluable for straight cuts. Proper selection and use of manual tile cutters guarantee professional results.

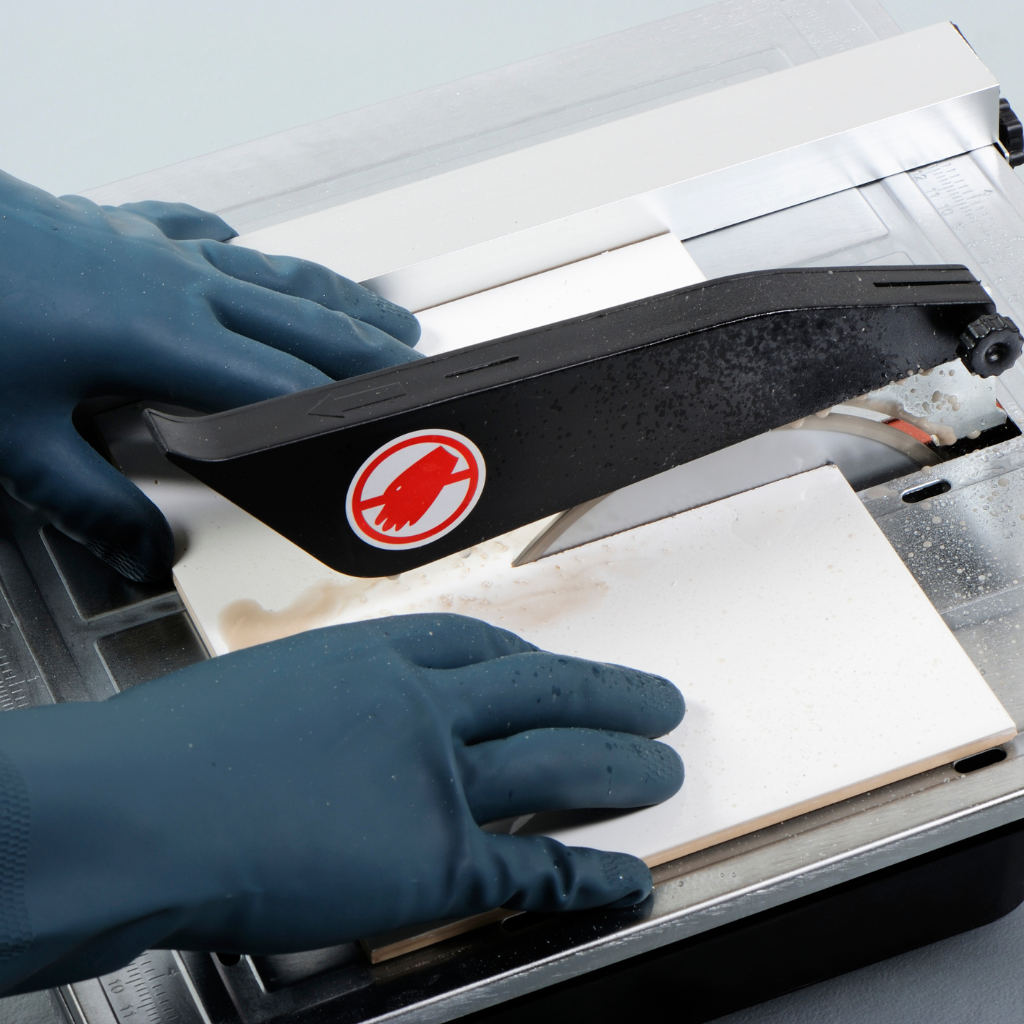

How to Cut Tile Using a Wet Saw for Precise Results

Among the most effective tools for achieving precise ceramic tile cuts, the wet saw stands out due to its versatility and accuracy. A tile saw, equipped with a diamond blade and a water-cooling system, efficiently cuts ceramic tile by minimizing friction and reducing dust.

This tool excels in making clean, straight cuts essential for professional finishes. To need to cut tile accurately, one must properly align the tile surface against the saw’s fence. The user should guide the tile towards the saw, maintaining consistent pressure to prevent chipping.

Mastery of these tools and techniques guarantees each cut is both precise and smooth. The wet saw’s ability to handle various tile sizes and thicknesses makes it indispensable for cutting ceramic with precision.

Can an Angle Grinder Be Used for Cutting?

While the wet saw is renowned for its precision in cutting ceramic tiles, an angle grinder presents an alternative tool for those seeking versatility and maneuverability. This tool allows users to make the cuts on ceramic tiles with a diamond-tipped blade. To minimize the risk breaking the tile, it is essential to guide the tile smoothly and apply consistent pressure. The technique involves marking the desired cut line, securely fixing the tile, and carefully aligning the blade with the cut edge of the tile.

| Tool | Key Feature |

|---|---|

| Angle Grinder | Versatile and maneuverable |

| Wet Saw | High precision |

| Diamond Blade | Essential for cutting ceramic |

| Straight Cut | Achievable with proper guidance |

| Risk | Tile breakage if improperly used |

This method demands precision and steady handling to achieve clean edges.

Way to Cut a Ceramic Tile Without a tile Cutter?

Cutting ceramic tile without specialized tools can be effectively achieved using like a glass cutter and a straightedge, creating a score line that allows the tile to be snapped cleanly.

Tile this way is ideal for small projects or quick fixes. For refining edges or making small, precise cuts, a tile nipper can be employed to nibble away at the tile, offering control over irregular shapes.

These methods offer practical alternatives that require minimal investment while still delivering accurate results.

Glass Cutter Methods Explained

Utilizing a glass cutter to cut ceramic tile offers an accessible method for those lacking specialized tools. To cut ceramic tiles, one must first mark the tile along the desired cut line with a straight edge. A glass cutter is then employed to score the surface, creating a precise line similar to cutting glass tile. Applying firm, consistent pressure guarantees a clean cut edge. Once scored, the tile is snapped along the line, producing a neat break.

| Tool | Function |

|---|---|

| Glass Cutter | Scores the surface of the tile |

| Straight Edge | Guides the cutting line |

| Tile Cutter | Alternative for precision |

Understanding these steps and tools allows for effective tile cuts without a traditional tile cutter, though a tile nipper may refine edges if necessary.

Using a Tile Nipper for Edges

A tile nipper offers an effective solution for refining edges after an initial cut has been made on a ceramic tile. This cutting technique involves using tile nippers to break small pieces of tile from the edge gradually.

The tool provides precision in shaping and smoothing the tile edge, especially where intricate cuts are required. This tile cutting method is particularly useful when straight cuts do not suffice, allowing for detailed adjustments without specialized tools.

To use tile nippers effectively, one must apply gentle pressure to avoid unintended cracking or breaking the tile. Each piece of tile removed should be small, ensuring controlled removal.

Mastery of this technique is essential for achieving clean, refined edges when knowing how to cut tiles accurately.

Why is Cutting Ceramic Tile with a Wet Saw Effective?

Cutting ceramic tile with a wet saw is effective due to its precision, reduced risk of chipping, and ability to handle various tile thicknesses.

Unlike manual tile cutters, a wet saw uses a diamond blade cooled by water, which minimizes dust and guarantees clean edges.

To achieve ideal results, understanding the step-by-step operation of a wet saw is essential, from setting up the tool to safely guiding the tile through the blade.

Advantages of a Wet Saw Over Other Tools

When precision and efficiency are paramount in tile cutting, a wet saw emerges as the superior tool for handling ceramic tiles. Unlike manual tile cutters, a wet saw offers a consistent water flow, reducing friction and preventing overheating. This method guarantees a cleaner cut, especially for dense materials like porcelain tile. The wet saw’s diamond blade effortlessly slices through the ceramic tile, producing a smooth cut edge. Allowing the user to guide the tile towards the blade gently minimizes chipping and splintering.

| Tool | Precision | Material Compatibility |

|---|---|---|

| Wet Saw | High | Ceramic, Porcelain |

| Manual Cutter | Moderate | Ceramic Only |

| Angle Grinder | Variable | Rough Cuts |

This versatility makes cutting tile with a wet saw an indispensable technique for achieving professional results.

Step-by-Step Guide to Cut Tile with a Wet Saw

Leveraging the benefits of a wet saw, the process of achieving precise and clean cuts in ceramic tile is systematic and straightforward.

Begin by marking the ceramic tile where the cut is intended. Position the tile cutter to align the blade to cut along the marked line. Place the edge of your tile carefully against the guide to guarantee accuracy.

Gradually slide the tile into the saw, maintaining a steady pace to avoid chipping. The water from the wet saw keeps the blade cool and minimizes dust, guaranteeing a smooth finish.

When planning to cut, make certain the tile is secured firmly. Consistent pressure helps make a cut that is straight and precise, enhancing the overall quality of the tile installation.

How to Make Clean Tile Cuts Every Time?

Achieving clean cuts in ceramic tiles requires precision techniques and attention to detail.

Utilizing a steady hand, proper alignment tools, and maintaining a consistent speed are critical factors in preventing chipping and ensuring a smooth finish.

Additionally, awareness of common mistakes, such as applying excessive pressure or failing to secure the tile firmly, can greatly reduce errors and enhance the quality of the cut.

Techniques to Achieve a Cleanest Cut

To achieve the cleanest cut on ceramic tile, selecting the right tools and techniques is paramount.

Begin by understanding how to cut ceramic tiles efficiently. When using a tile cutter, verify the cutting wheel aligns with the tile along the line marked on the face of the tile. Apply consistent pressure as you push the tile, guaranteeing the score line penetrates the surface of the tile uniformly.

For sections where a tile cutter cannot reach, a grinder may be employed to cut accurately. When using a grinder to cut, maintain a steady hand and verify the blade remains perpendicular to the tile.

Common Mistakes in Cutting Ceramic and How to Avoid Them

Cutting ceramic tile often involves common mistakes that can lead to imperfect results, but understanding these errors and how to avoid them can guarantee clean cuts every time.

A frequent error is improper tool selection. When consider cutting the tile, using a tile cutter designed for the specific material is essential. Specialized tools are required for precise curves or when cutting a hole in ceramic tile.

Overlooking tile edge finishing is another mistake; a tile file smoothens edges after cutting. Additionally, failing to secure many tiles you plan on cutting can cause slippage, leading to uneven cuts.

Measuring inaccurately or rushing can also result in errors. Ensuring the correct method makes tiles easy to cut efficiently and accurately.

What Are the Challenges of Cutting Ceramic Tile?

Cutting ceramic tile presents specific challenges due to its inherent fragility and susceptibility to cracking under stress.

Achieving precise, straight cuts requires meticulous technique and appropriate tools to prevent chipping and guarantee clean edges.

In addition, unlike natural stone, ceramic tile’s uniform composition necessitates a different approach to maintaining structural integrity during cutting processes.

Why Is Ceramic Tile Fragile and Prone to Cracking?

Although ceramic tiles are widely favored for their durability and aesthetic appeal, they are inherently fragile due to their composition and manufacturing process. This fragility arises from the hard ceramic tiles dense structure and the presence of micro-cracks formed during kiln firing.

When attempting to cut ceramic tiles, factors such as stress concentration and improper handling can exacerbate the likelihood of cracking.

- Material Composition: The brittle nature of the ceramic makes it prone to cracking, especially when using a cutter that applies uneven pressure.

- Stress Points: Any imperfections or inconsistencies in the tile to must be cut can lead to unexpected fractures.

- Cutting Process: Working with tiles requires precision; even slight misalignments when attempting to cut a few tiles can result in chipping.

Understanding these challenges is essential for achieving successful cuts.

How Can You Achieve Precise and Straight Cuts?

Achieving precise and straight cuts in ceramic tile requires meticulous attention to technique and tools. For those who want to cut ceramic tile with precision, marking a clear line on the tile is essential.

Using a pencil or marker, draw the intended cut line. When questioning, “how do you cut ceramic tile without a tile cutter?” one effective method is scoring the line on the tile’s surface with a glass cutter or utility knife.

Position the tile so the scored line is overhanging an edge, apply pressure along the first cut, and snap the tile along this line. If a smooth edge is needed on the side of the tile, sanding or filing may be necessary.

This method guarantees a straight and clean break.

Differences Between Ceramic and Natural Stone

When considering the differences between ceramic and natural stone tiles, one must understand that each material presents unique challenges in the cutting process due to their distinct compositions and densities.

Ceramic tiles, often more uniform and less dense, can tile to be cut with a wet saw or even tiles by hand. In contrast, cutting natural stone tiles requires knowing how to cut with precision tools due to their irregularity and toughness.

- Ceramic tile, like cut glass, requires a delicate touch, especially when attempting to cut a tile in half.

- Cutting natural stone tiles often necessitates specialized equipment to allow you to cut efficiently without damaging the material.

- Using a glass cutter for ceramic tile can be effective for thin pieces, and cutting ceramic tile using a glass cutter enhances control and accuracy.

Conclusion

To sum up, mastering the art of cutting ceramic tiles involves understanding the appropriate tools and techniques for precise results. While specialized tools like wet saws offer accuracy and reduce breakage, alternative methods can suffice when tools are limited. Achieving clean cuts consistently requires meticulous attention to detail and careful handling of materials. Despite challenges such as tile hardness and potential chipping, with practice and the correct approach, even complex projects can be executed with precision and efficiency.